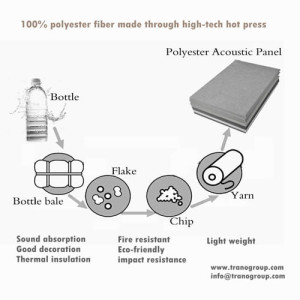

Polyester fiber panel is a new kind of echo panel more and more engineers choose TRANO POLYESTER ECHO PANELS to reduce noise and protect human hearing.

The following is the manufacturing process of TRANO PET Sound Absorption Panel.

Mixing

The feeding machine will mix LMF(low-melted-fiber) and posted industrial fiber based on suitable proportion.

Homogenizing

The big trunk machine will homogenize all kinds of fiber together completely and equably.

Hackling

The carding machine will hackle the material to be loose and sparse fiber layer.

Stacking

The bamboo-raft machine will stack sparse fiber with 300-400 layers to enter into preforming press.

Punching

The needle machine will punch the thick-layer fiber to high density via adjustable speed and thickness.

Heating

The heating machine is a partly enclosed, directly heated surface from which warm air circulates by convection. It will make LMF melted to bounding all fiber together.

Pressing

The multiple rollers will press the melted fiber to demanded thickness.

Cooling

The hydro cooling system will fix the panel thickness and shape.

Cutting

The auto-cutting machine will cut the settings size

Ripening

During a 48 hour period, panels stay in a stabilization process.